Rotary Airlocks

Blow Through Rotary Airlock Valve

Specifically designed for pneumatic conveying applications the Blow Through rotary airlock is one of the most common style of rotary valve used in pneumatic conveying. Blow Through rotary airlocks provide a high efficiency throughput with a low effective drop in pressure making them very reliable and cost effective.

Click here to read more on Blow Through Rotary Airlocks

Drop Through Rotary Airlock

Drop Through Rotary Airlock

Drop through rotary airlock feeders are designed for rugged applications, designed with a thick housing and blades with out-board mounted bearings for maximum reliability in high temperature applications.

Click here to read more on Drop Through Rotary Airlocks

DDV

The DDV Dust Duty Drop-Thru Valves are designed to provide a low cost airlock solution for simple light duty dust collection applications under baghouses and cyclones. They are available with robust cast iron or stainless steel housing and end plates. Direct Drive as standard.

Click here to read more on DDV Drop-Thru Valves

UDV

The UDV Universal Duty Drop-Thru Valves are designed for economical and reliable material metering and airlock service. The perfect solution for low pressure pneumatic conveying. Ideal for pollution control applications beneath dust collectors and cyclone separators.

Click here to read more on UDV Drop-Thru Valves

HDX/HDXP

The HDX Heavy-Duty Drop-Thru Extra Tough and HDAR Heavy Duty Abrasion Resistant and HDXP Heavy Duty Explosion Proof rotary airlocks are designed to withstand high temperatures and pressure differentials. This legendary design sets the standard by which all others in the industry are measured. It offers the heaviest gauge rotor vane stock of any competing product, extra thick endplates, flanges and housing walls, along with outboard mounted oversized bearings that are prelubricated and permanently sealed to ensure low maintenance and prolonged life. The HDXP design meets all of the current NFPA requirements.

Click here to read more on HDX and HDXP Rotary Airlocks

Klean in Place II

The KLEAN-IN-PLACE II rotary airlock valve is specially designed for applications where frequent cleaning, sanitizing or inspection of the bulk handling system is required. It’s uniquely designed features makes it compliant for FDA, USDA, 3A dairy and NFPA standards.

Click here to read more on Klean in Place II Rotary Airlocks

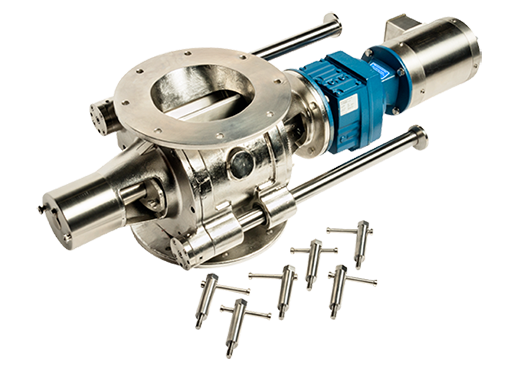

Kwik Klean

The Klean-In-Place® rotary airlock valves are specially designed for applications where frequent cleaning, sanitizing or inspection of the bulk handling system is required and minimum downtime is critical. They are also ideal for batch systems where regular cleaning between cycles is required. These valves need no tools to unscrew the release handles and remove the headplate. Four slide bars provide maximum support for the rotor so it can be pulled out exposing the valve interior so it can be thoroughly cleaned, sanitized and inspected.

Click here to read more on Kwik Klean Rotary Airlocks

Double Flapgate

Both cast iron and fabricated double flap valves are available for various applications. Heavy duty construction for the most abrasive applications.

Click here to read more on Double Flapgate Valves

Pneumatic Screw Pump

Meyer Screw Pump is a heavy-duty dry material injection pump, designed to feed dry pulverized material into a pneumatic conveying line. The Screw Pump works where other dilute phase feeders have failed due to problems like abrasive wear, friable materials or fine material dust. Unlike rotary airlocks, which require tight clearances to seal against the conveying air the Screw Pump utilizes conveyed material to form a seal. An integral gate prevents blowback when priming or running empty. The Screw Pump eliminates blowback and early failure from abrasive wear; it reduces excessive maintenance and unplanned, costly downtime.

Click here to read more on Pneumatic Screw Pumps

English

English